Line in the middle of every print?

I'm sure i saw a post regarding this problem in the past.... I'm using cura as my slicer. Every print i do I have a distinct line kind of in the middle of the print. It is especially evident when making lithopanes. Does anyone know if there's a setting in cura that needs changing ? If I can figure out how to attach a pic I will

Generally great print quality except this curve?

I redone my belts with the GATS system tensioning my belts equally across all 4 of them to approximately 4kg, and made the belts equal size. The belt tension feel's lower than I'd of done it to manually. Whilst doing this I re-squared my gantry too which has improved my VAOC results. Overall my machine moves as smooth as it ever has but..

I'm getting this bumpy, wavy wall on what should be a smooth curve though?

Any help greatly appreciated...

Model size not matching the print

Hello, I have been calibrating my printer after rebuild and ran in

to issue, that when I place model (80x10x4mm beam) on the bed in either X or Y direction, it prints pretty fine, the dimensions are 79,8, 9,95 and 4,05mm. But when i place them 45 degrees to one side, the print is 80,5mm long and to the other side its 79,5mm long. I generally think its a belt tension problem, but any advice will be greatly appreciated....

Weird blobs and gaps in print?

I’m using a new roll of petg filament to print a large 990g, 12 hour print on my vcore 4 idex and it’s having an issue printing with these bits sticking out on the walls. There is no seem anywhere on that face and it does it all around the print. I tried to reprint with slightly lower temp, 250c and it’s still basically the same. I’ve done many smaller prints without this issue? My guess is the stock spool holder has to much drag and when it’s being pulled it skips a bit? But I guess that wouldn...

Solution:

i get artifacts like that if the spool isn't dry. Try drying it out and print again

Core v4 raspberry pi USB shorted out

I'm in need of a support person to figure out what I have done wrong with the build on this core V4 build. Everything was fine to begin with on the first power on everything was lighting up correctly but the raspberry pi just kept blinking red and wouldn't blink green or hold the green LED. I unplugged the printer and pulled the SD card and reimagined it and tried again but this time the red light flicked red once and turned off it then started emitting smoke from the usb that the big tree tech...

IDEX offset of T1 on the far side from VAOC

My issue is the prints coming out of my T1 is a kind of rotated regarding the prints from T0. Close to VAOC they're perfectly fine, but on the other side of the bed there is half a millimeter offset. What I did:

- Checked the rear plates with the motors (unscrewed and screwed again, to be sure they're flush to the profile).

- Adjusted the anchoring of the belts to the heads in order to make the front tensioners extend the same amount. It should make the length of both belts pretty much equal.

- Shaper graphs are good. Very low vibration percentage (under 2 for all). Y belt above 5700 MZV, X belts over 7500.

- The frame is quite well assembled. I've measured all diagonals and they have way less then 1 mm difference. ...

Make box align

Trying to get the two parts of the lid to align. But seems I am printing something wrong. In both sides the parts that are trying to align are the upper part of the print.

Printer in ASA, so my guess is some kind of shrinkage issue?...

Sharp corners on small part being rounded

Part on left is from Ender 6 with default settings (80mm/s). Part on right is from VCore 400mm RatRig slowed down to 40mm/s. I've usually been printing at 250mm/s with the RatRig but I slowed it way way down trying to get rid of the rounding to no avail. I did the automatic input shaper calibration a while ago, but I will do it again if that would help. I believe the belts are the correct tightness, but I am open to opinions there as well. I've also attached an image of the settings from Cura (Ender 6) and Prusa (RatRig).

Any suggestions would be great. Thanks!...

Zits on travel moves (I think)

noticed that my ASA print has these zits on the outer walls where I think travel moves occur, since they're all pretty random aswell. There's no extra extrusion, more like a pinhole. I have "avoid crossing walls" enabled in my OrcaSlicer, but it seems to still cross them anyway if I look at it this way. Retraction settings included

Layer pattern

Hey guys,

Does anyone of you know where this weird pattern comes from and how to avoid it?...

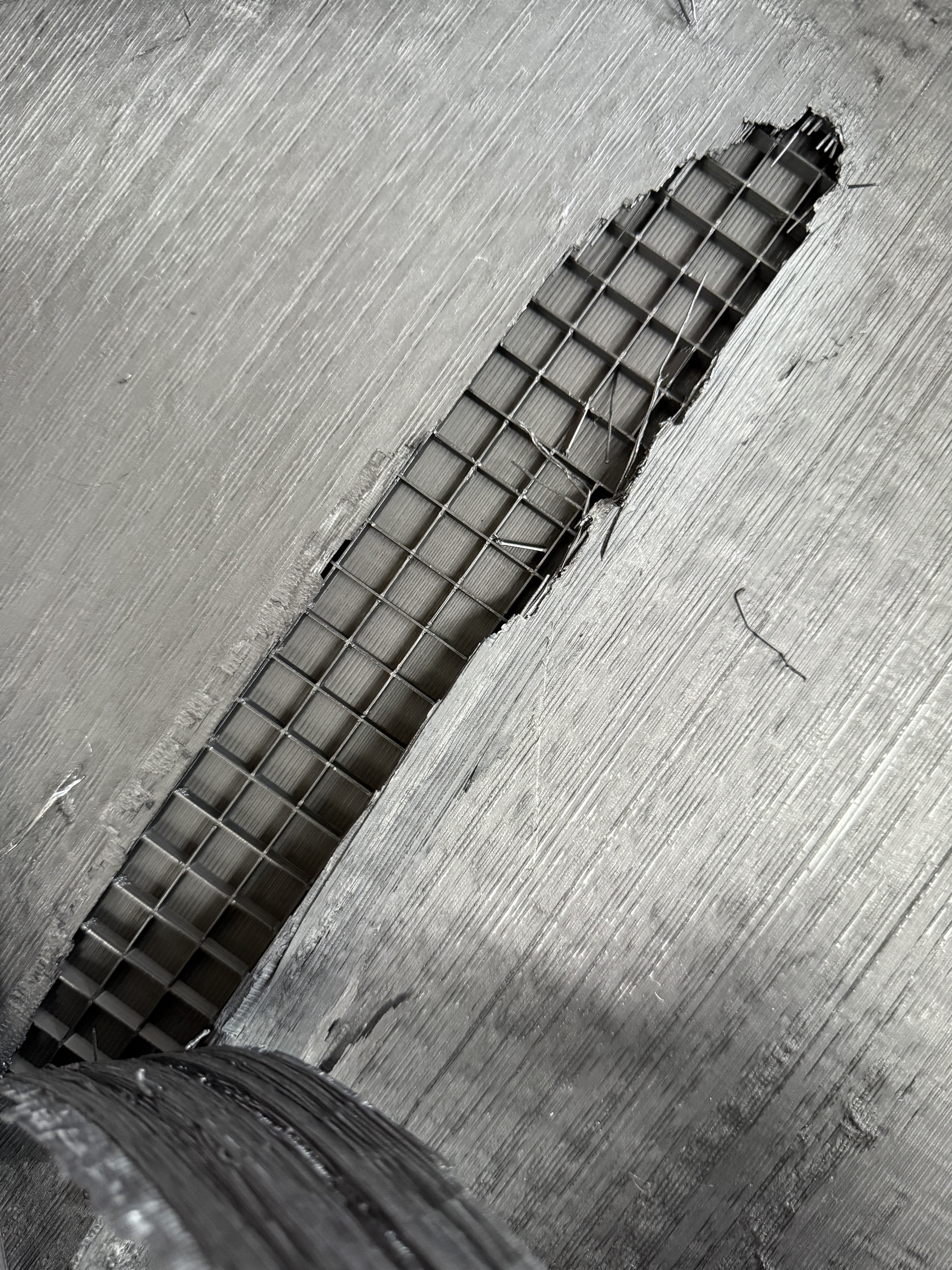

ESUN ePAHT-CF bridging issues

I'm able to print just fine but bridging is a pain with eSUN ePAHT-CF.

Even overhangs are fine without any fan at all but this bridge in the photo below was printed with 25% fan, it didn't help much at all.

I'm using a 0.5 TC nozzle, filament is properly dried for days @70°C and then three hours @90°C right before printing.

I tried 30mm/s bridging speed, 60mm/s bridging speed (the filament profile is limited to 10mm³ anyway) but nothing helps.

Even though it's just a single 5015 fan for cooling, I don't feel comfortable ramping it up to 50% for a PA-CF filament, although that is what I'm going to do now....

Abrupt Z offset when printing in different C direction

I am printing a different material than plastic, but I think the problem can be applied generally.

As you can see in the image, the print immediately stops after the curve when printing in opposite x direction. The sample lies in the corner at the zero point of a ratrig core 3.1

Do you know what could be the issue? I was thinking if it was a bed mesh issue than the print would gradually stop, and not immediately after the curve....

Layershifting

Thanks a lot again everyone for helping out, i think i might be close to getting it sorted now, after fixing the calibrations and offsets, pa and flow cal, this is what it did overnight, i did print some layers at the bottom properly, but then did this zigzag. The central layers also did not get stuck to the support underneath them.

What am i doing that is causing this issues....

Z-Offset wanders a bit a the beginning of each print

Hey!

I am currently having the problem, that my V-Core 4s prints start off with a bit too high of a z offset. After a while, Id say about 2 or 3 minutes, the offset gets better, until after about 5 minutes, its perfect.

This problem does not come down to a warped print bed, as, even when the print head returns to the exact same position later, the offset that was of at the start, is now perfect. (See picture)

...

First layer test is good, skew test fails: nozzle hits after a couple of layers

The nozzle hits the print or i am assuming its extruding more. I have changed the speeds as well as the multiplier to 0.62, it did print better for some layers but did the same thing again.

I have atached pictures of many of my skew test and a model i tried printing.

thanks for help and advices...

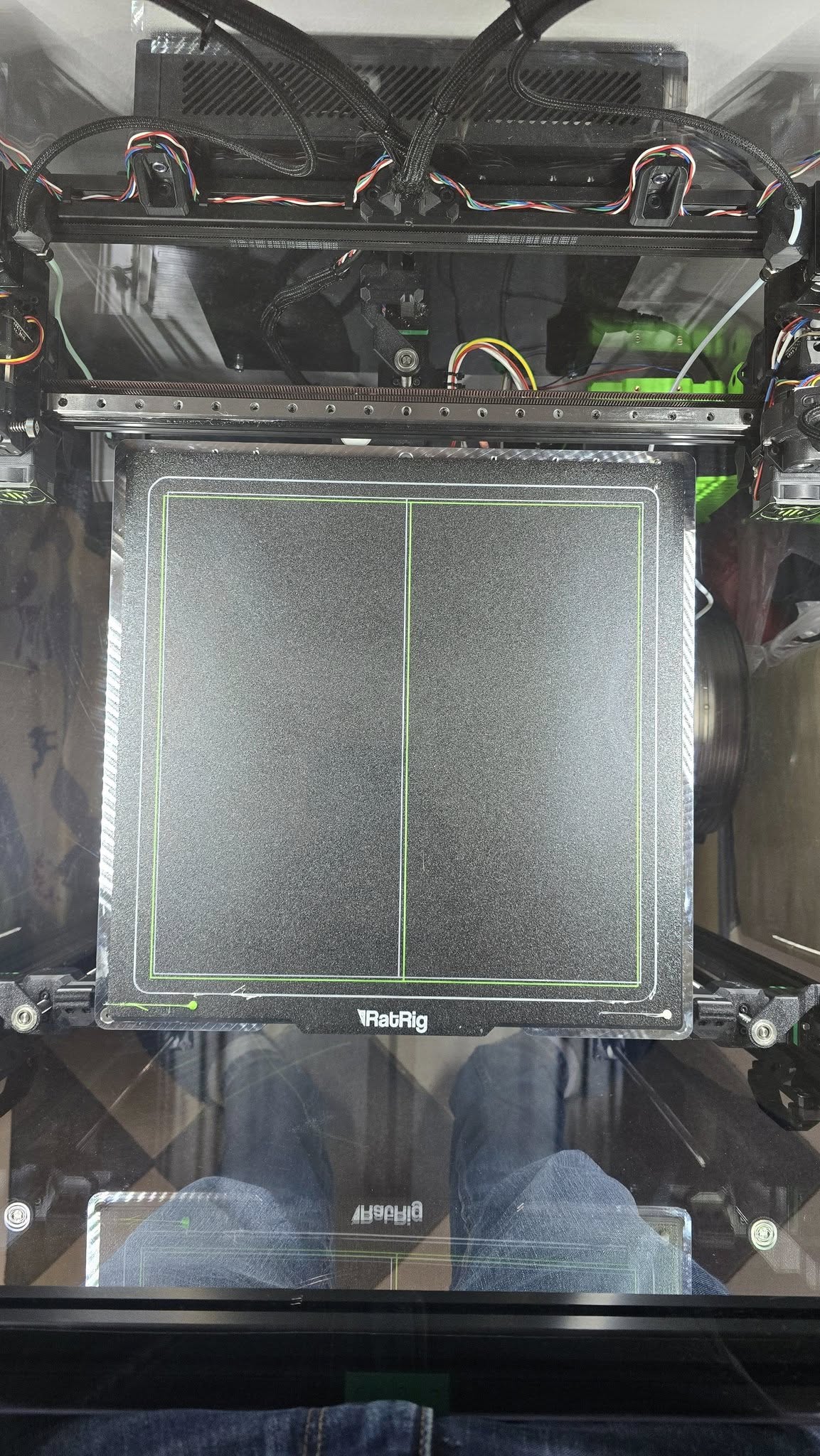

V-Core 4 hybrid back benchy sign

Hey i recently build v-core 4 hybrid and printer few parts with awesome results. Made benchy and it came out almost perfect but not the sign "stern" on the back. Any tips? Nozzle 0.4. Easy pet-g in black matte from fiberlogy. 260C and bed 90C. Speed 200mm/s accel 12k. Part cooling fan in default ratrig settings.

Horrible print quality

Hi there - I can’t seem to get my printer to print right - here is the latest cube. I’ve not seen anything like this so i don’t know where to start.

Solution:

Was using .6 nozzle instead of .4

X axis drift on v-minion

This is my printers version of a cube. I've tried switching slicer, it did not help. I've oiled the rails as it was having more wiggles and I thought it might had been that. I had no issues printing stuff for Christmas. It's been unused for a few weeks, so I updated it when I started it. And then these issue appeared

Mainsail thinks it's printing a perfect cube, it certainly is not a perfect cube. Does anyone have a solution or do I have to reflash it again?...

Solution:

Solution:

Retightened the thing in the photo, tuned the x axis belt, some good old sewingmachine oil(on the rail and carriage)...

Benchy Bow Curling

I'm attempting to increase my print speed with PLA+ on my Vcore 3.1 (Eva 3.0, 4048 fan with mosquito hotend and orbiter v2.5). Previously I've been able to print a benchy at about 34 min without any artifacts but I'm trying to achieve a 20 min benchy. I'm having issues with the bow curling up during printing. I'm also running into a problem with orca slicer limiting my flow rate lower than what I've set it to (changing to 0.2mm layer height fixes this).

Things I've tried: reduce temp from 220 down to 215,210,205. Enablling and disabling overhang slow down at curled perimeters.

- 2 perimeters, 10% infill, 3 bottom and top layers. 0.25mm layer height, 0.4mm width....