Uneven belts tension and square xy

Hi. I keep struggling with un even belt tension reported by belt-tension script, but my x gantry seems to be perpendicular to y rail (checked by moving it to the front and measuring distance from extrusion by calipers)...

102 Replies

or should I just accept it as belt tension seems to much at 50hz?

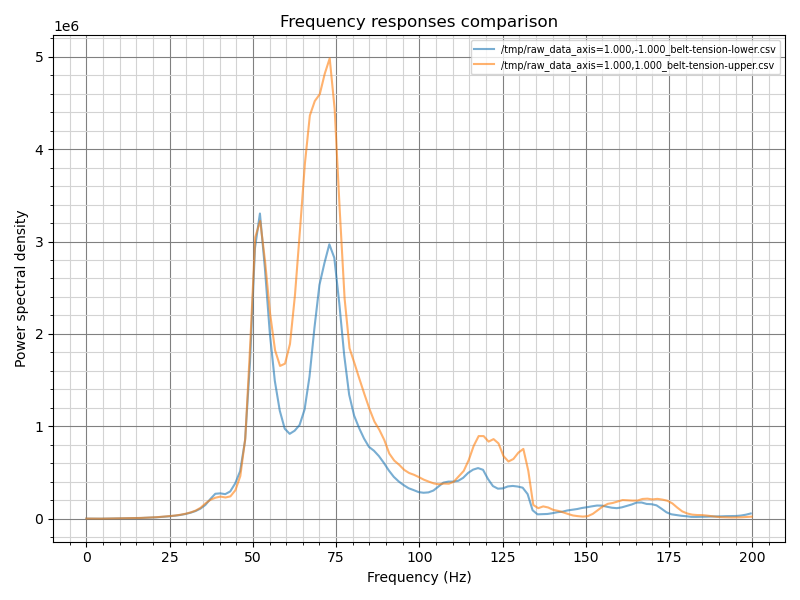

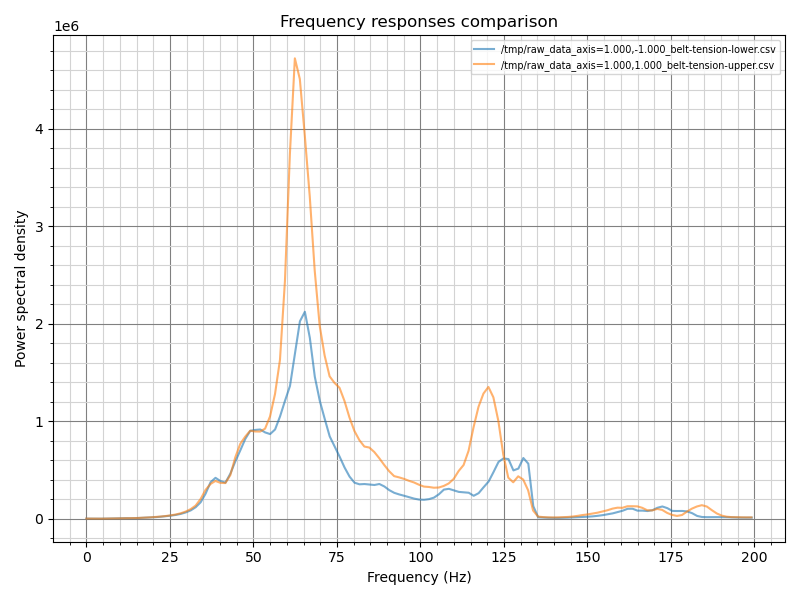

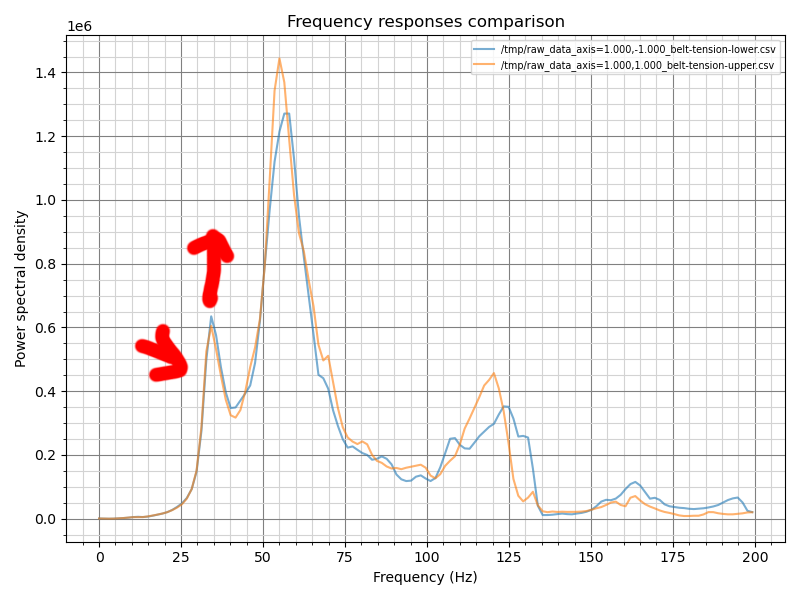

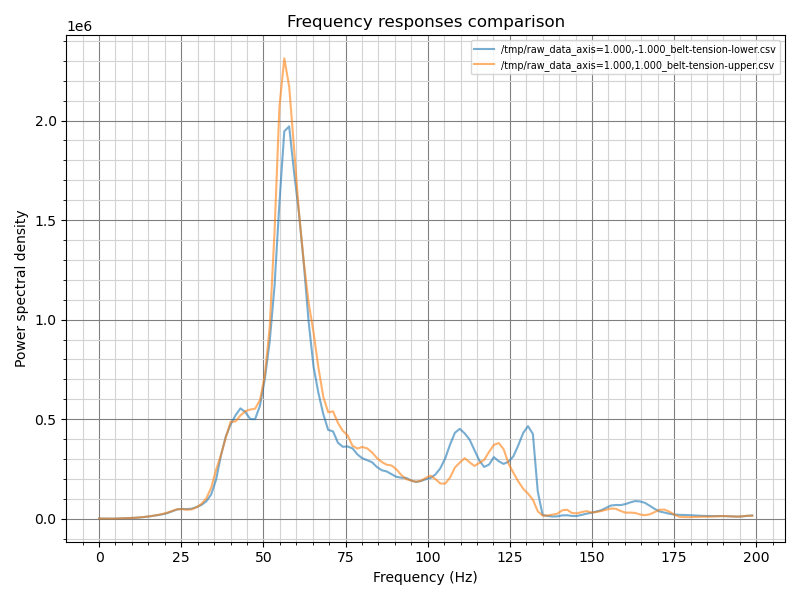

This weird graph start to appear after I swapped xy-joints and top motor cages, so it did not just start to show up from nowhere, before it looked like that:

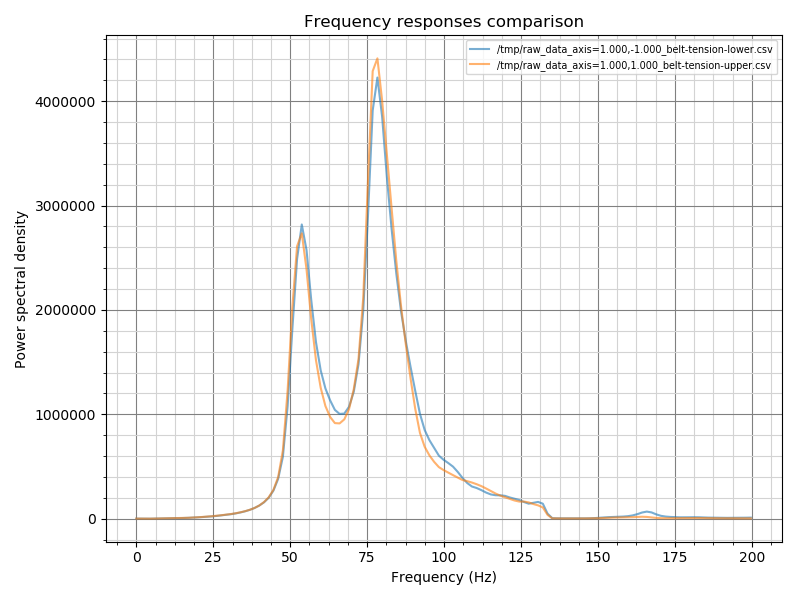

4.0 on 1e6 - that seems overly tight to me. mine is like 1.5

Oh, So I should make them less tight?

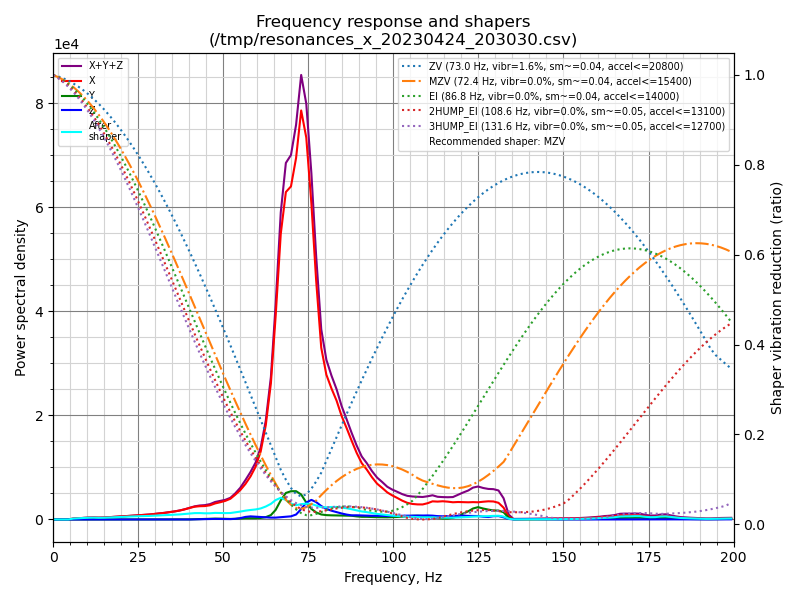

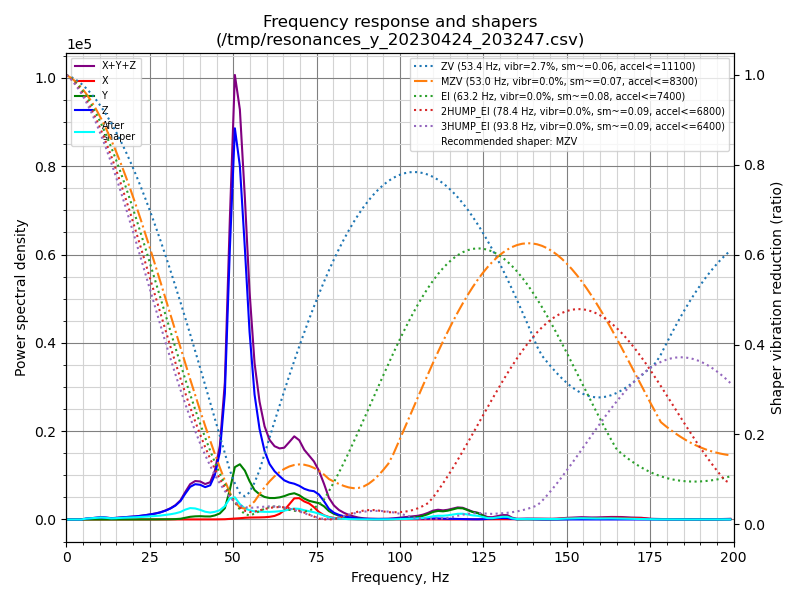

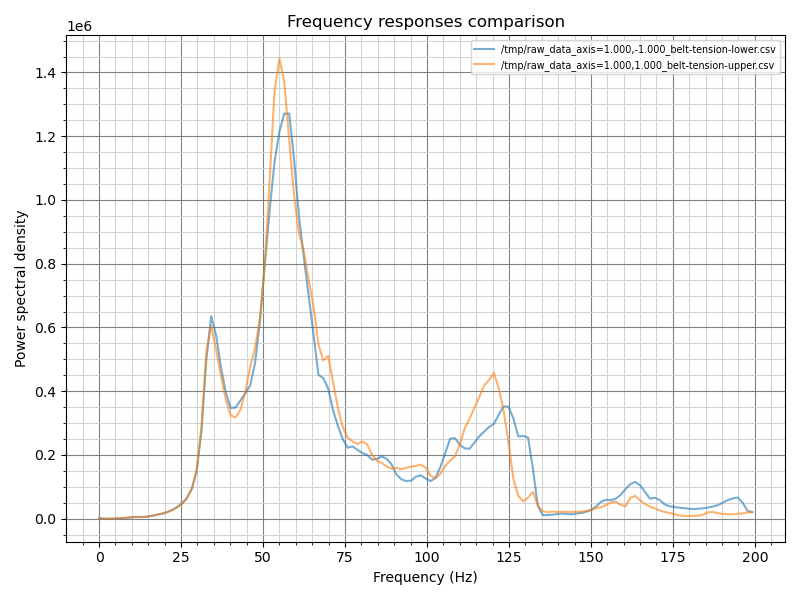

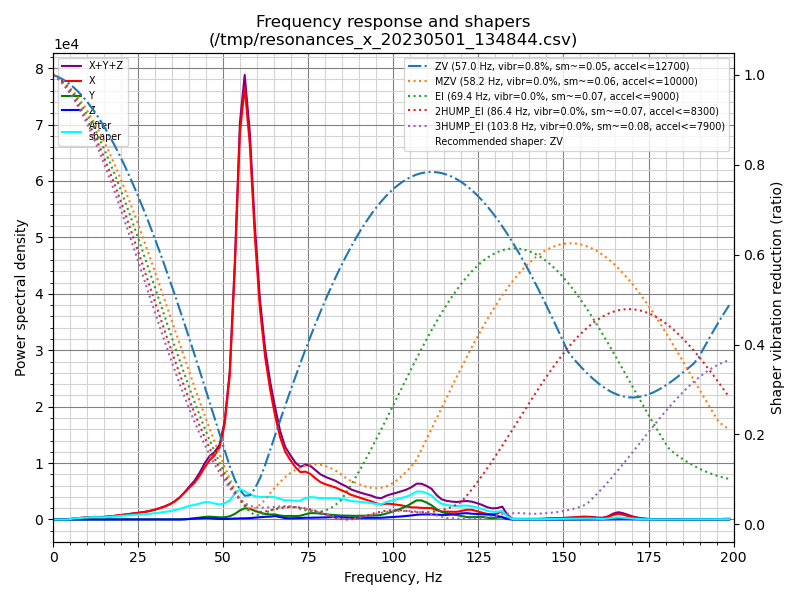

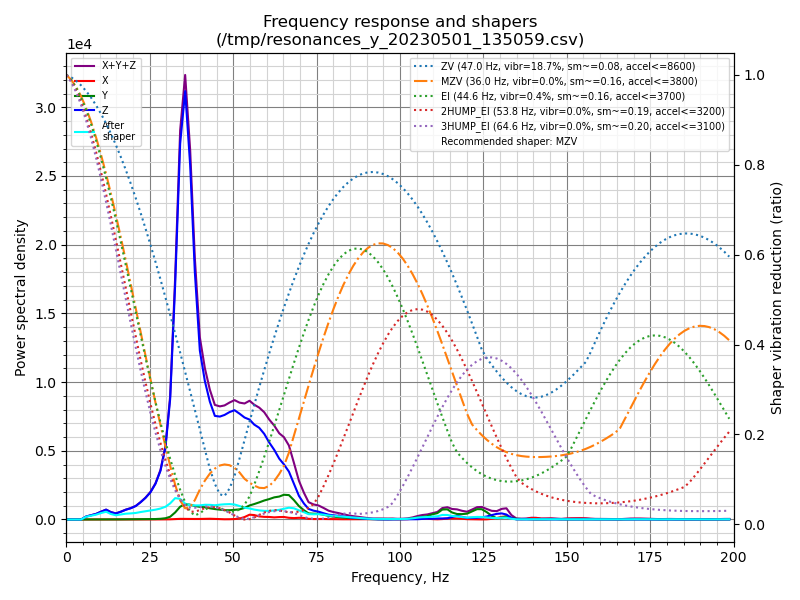

my shaper graphs if it might help:

I will try to unscrew both tension screw by two rotations then

Though @miklschmidt said on similar graph in #general that this is perfectly normal.. (4.0 on 1e6)

to each their own - I run mine at 1.5 and that works fine for me

and with less tension things will last longer

Got it. Running script after lowering tension by 2 rotations

I would also keep in mind - your machine will still print well even if things aren't perfect

welp, I lowered tension, but still keep getting same uneven results

If I try to tight lower belt, my x rail becomes not perpendicular to y rails

It says your upper belt is tighter than the lower one

yep, but if I change it - axis become not perpendicular...

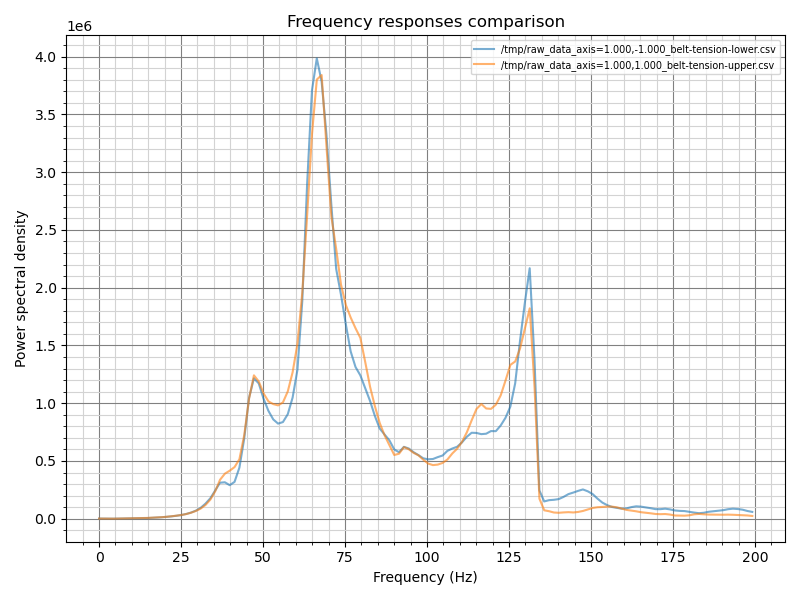

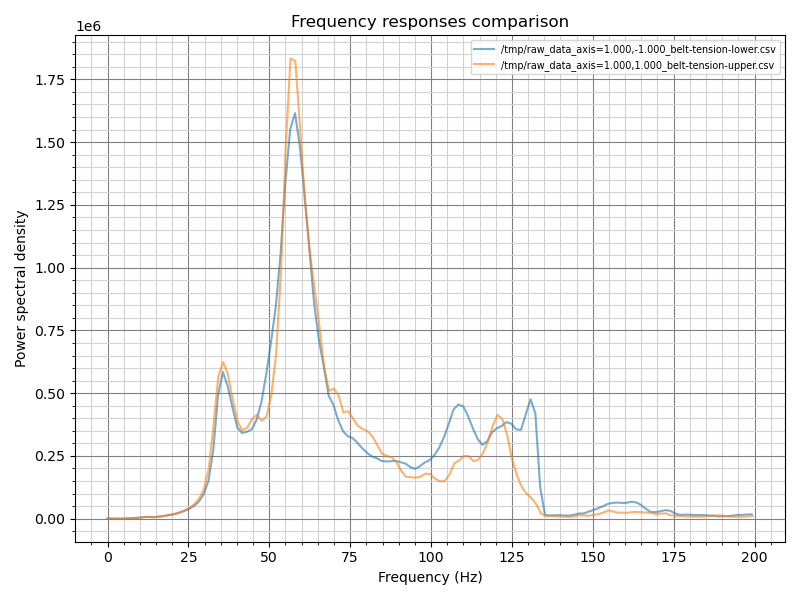

btw, after lowering tension I got this:

you might have uneven belts or you didn't ensure your jointer plates are square

jounters plates are square?

Sorry, how whould I check it and fix it?

I used 123 blocks to hold the X axis parallel to the front of the frame with clamps and then tightened the jointers down

hmm, so your suggestions is to completly remove belt tension from the equation by loosing them completly and then try to reasemble xy joints?

The most important part of the belt tension graph is that the peaks line up

but they dont xD Hi

the difference in amplitude does indicate that one belt is stiffer than the other, this can be due to stretching.

the first one you posted did

Oh

It can also be caused by loose screws / parts etc etc

Or belt riding on idler flanges

etc etc

Okay, that is... intresting. Thanks

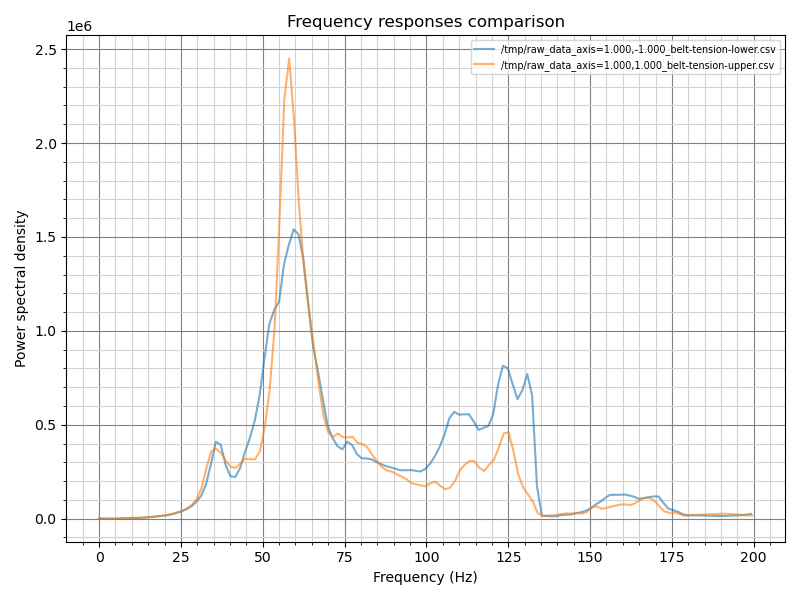

Hmm, it seams to get... Better? I lowered tension in both belts and then realign axes

Sorry for stupid questions and chaotic conversation, just have no expirince with that stuff,

Gotta start somewhere! 🙂

And I tweaked a bit more on got this… just a bit of turns back and fort

I looked into guide on how to read graph, and as you said - peak alignment is important, height is not

So I guess I will just stop on archived 😂 Or would you recommend try to fix it?

I would prefer https://discord.com/channels/582187371529764864/1100154509461835796/1100179903946690660 over https://discord.com/channels/582187371529764864/1100154509461835796/1100191522672099438

Just relax the tension a tiny bit on the lower belt there and you should be good.

If I interpret you right, you measured squareness of your gantry by using calibers to the front extrusion. If so then what you measured is not perpendicularity but whether the two are parallel to each other. Just saying because if your top plane is not really square but you take it as such, and then use that as a measure for your gantry perpendicularity, you're graphs are going to confuse you.

Probably you are right, but I tried my best during assembly of the frame, don’t know better method to check if axes are perpendicular😅

a decent machinist square or https://www.calculator.net/triangle-calculator.html

Triangle Calculator

This free triangle calculator computes the edges, angles, area, height, perimeter, median, as well as other values and a diagram of the resulting triangle.

Then I will try to get same results again😂 Thx

Okay. So, with such graph I have axes not perpendicular but at least 1mm, I checked it by machinery square and calipers.

And for this check I used same machinery angle which I used to assemble the frame, so this is for sure not machinery square fault....

I think that means your belts arent the same length

your belts are probalby binding somewhere

you should have 2 main peaks

means your belt grinds somewhere some metall or most likely plastik

forgotten shims can also be a cause

hmmm. Good guess, I did not make sure that I have equal belt lenght, as I thoough it wont matter

As there is decent belt tension mechinism, which works

hmmm, my carrege moves super easily

is this a 200?

It is 300mm

if you think your bvetls are fine then try to change the tension

you were almsot there

the left peak jsut should be a bit higher

not as high as the second one

It was at lower belt tension, and if I remember right - at that graph axes were not square…

I tried to check squareness of the frame by measuring diagonals, seems in +-0.25mm

this is the goal

But what is more important, equal belt tension or perpendicular axes?

both

equal belt tension, same belt length, squareness, ....

its all needed

Welp, if my frame won’t be square, equal belt tension not equal squrness

Or idk what makes my axes square at uneven tension

test if your belts have the EXACT same length

Okay, I will check for it, thanks

i mean really exact

like the exact same tooth count

But won’t tension mechanism compensate it?

How could I check belt equality without removing belt completely?

I don’t have fmmm mod and this is struggle to put it back in

Or there is no such way?

you cant

All clear, task understood

Thanks

dont do it now

try to get the FMMM Mod and then do it

Welp, my frame was not square, and my square is not square too as it report >90 deg angle on all corners

I need good machinist square before I put printer back together 🤡

I bough more reliable square, checked again, I some how have ~90deg angle at left and right top corner and >90deg ad back corners

How could this be possible?

some extrusions must be skewed

or unequal length, or/and with gaps

Hmm, maybe maybe, but unfertenatly, no method to check it. Kit is original ratrig kit.

what i mean is that you havent squared the frame well enough

As I remeber from trigonometry, it is impossible to assemble shape out of 4 sticks, which will have two 90deg angles and other two >90deg xD

So, ither sticks are not strait, or my top part of the frame is not in the same plane

but my bed mesh has only 0.15mm diff, so - I guess it is - in the ~same plane

You said ~90deg 😉

and not meaning to argue or prove my right, I thought it was helpful to give you something to check that you could have possibly overlooked.

yep. it is definitely helpful, thank you!

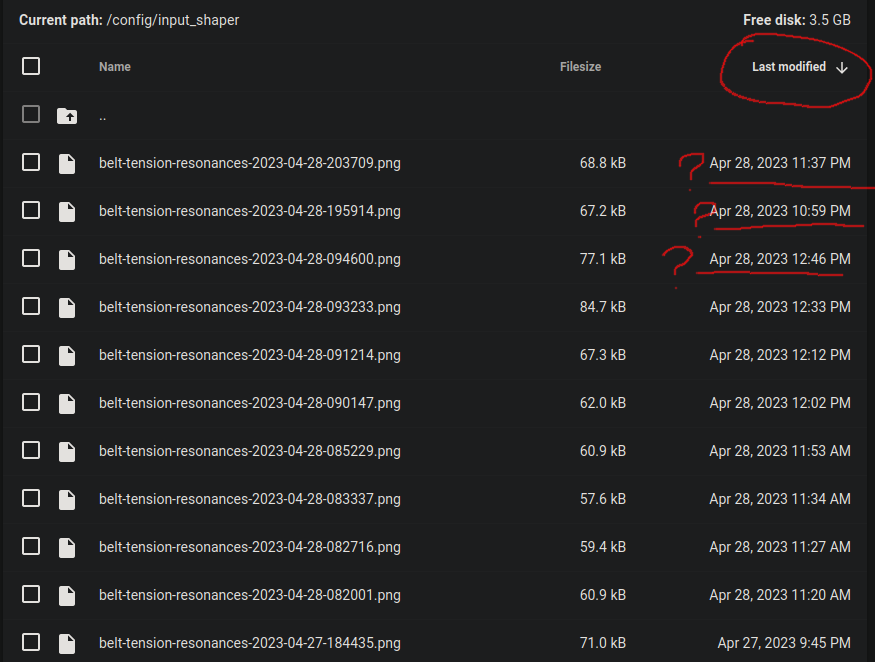

I thing I found source of all of mine problems

Just what the fuck

I have been looking into some random graphs

because mainsail did sort them like piece of garbage

timestamps on fs are correct btw

Wow that sucks 😟

ps. I just checked and have the same issue

sorted by name by default. ZERO always lists off first. Simply click on the ' modified' column title if you wanted it sorted by date. seems normal to me. Linux and windows both do that

Check ‘modified’ column, it is selected (arrow next to it)

But result is still sorted by names

In a terminal, when I use

ls -alht, where t sorts by time and, as the man page for ls explains, uses modified time by default, the output for the input_shaper files is different than in mainsail when clicking the last modified column header. Its not sorting correctly IMO. @maba_kalox screenshot above shows its not correct.How could I measure belt tension without using macros?

I feel like something could be wrong with adxl or something else, because if I follow graph and tight until graphs matches, by hand I can feel that belts actually have different tension

There are people who use the microphone on their mobile device to measure the frequency when picking the belt like a snare on a guitar. Personally I don't trust that method for several reasons I don't want to get into, but you could give that a try. Did you ensure your belts are equal length? I mean, to the tooth, equal?

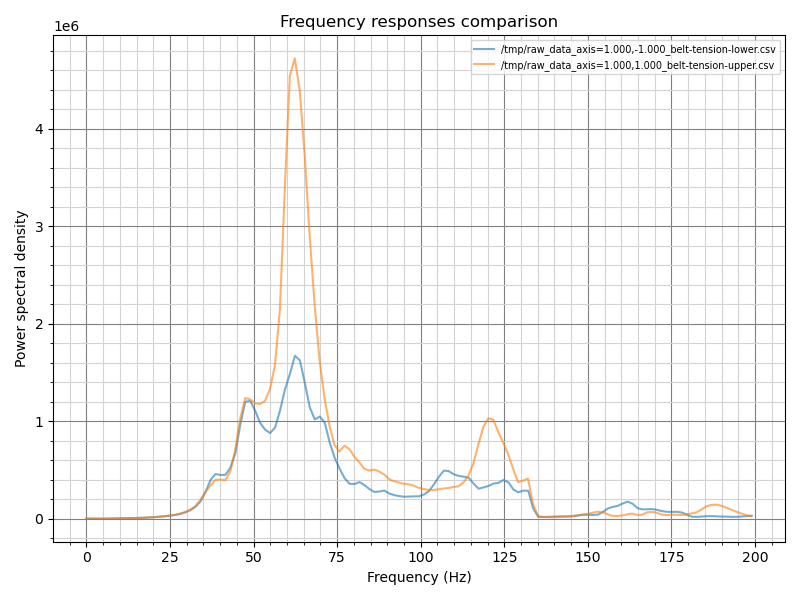

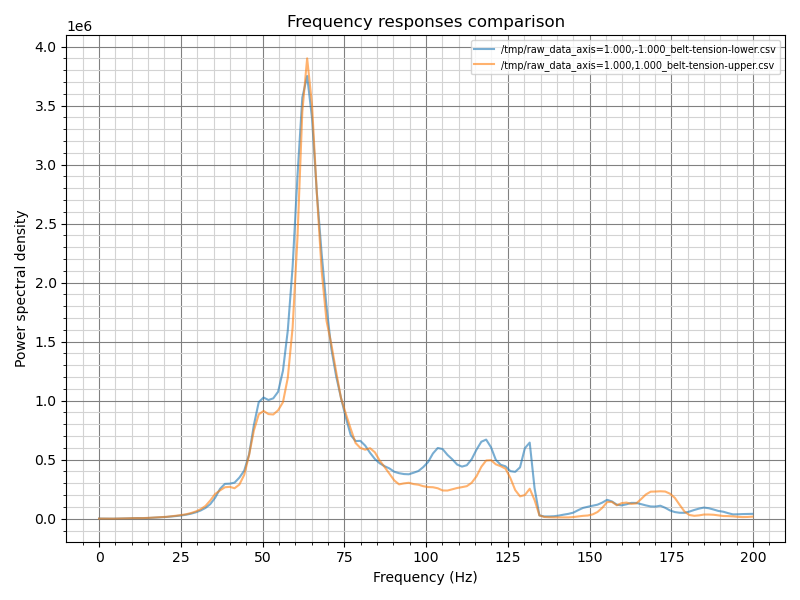

issue resolved, the reason seems to be - a table... Graph on table:

Graph on floor:

aside from the base for the printer (floor/table) nothing was changed, so gaentry is still perpendicular and belt tension was not changed.

Shouldn’t the Y axis have a second peak at ~40-50Hz?

it should, but I have no idea what could it be. I mean. I have small peak...

but something cancels it out. IDK what

That’s a bit better, yes

that is graph on the (fixed) table

by fixed I mean - I added/removed pads under the legs, to make it more stable

my shaper graphs:

though this boob on y axes around 60hz looks suspicious xD

The „hill“ around 50-70Hz on Y looks not right, yeah.

Did it move smoothly without the belts?

hard question, I aligned gantry by belt tension and only after fasten it

How large is your printer?

300mm

Then I think that the resonance frequencies are a bit low. It could be that both belts need to be tighter (by the same amount).

But maybe wait for experts on this, before you ruin it

As long as you don’t hear the belts slapping against the extrusions during resonance testing, it may be ok

Opinion differs, someone suggest to have 410^6 power density, someone sugges aroud 2 10^6

they slap xD

I don‘t mean the peak value, but the frequency, where the peak is

Ok, if it slaps, then it’s definitely too low

For me, tightning, change the peak height too

so, they should be, that tight, that during belt tension test they dont slap at all?

I was told that slapping during the test does not mean the belts are too loose.

Hmm. Lets wait for third opinion xD

by someone on the R&D team 😉

Yeah, better to wait ;)

But during normal printing they should not slap

I will try to print calibration cube with current tension, and check how bad is it.

they slap for me only on reasonance frequencies

So not all the time, but rather at peaks

That makes sense

best bet - take a video of this slapping and show it too us

Gates (the belt mfr) even sells a device for belt tension via sound. This method is ages old and widely used in industry. Even my CNC mill lists the belt tension via a resonant frequency (and it's a tiny center to center vs the RR machines.) Florent posted a great write up he did for the RR machines (BRS-Engineering website) He used Gates own belt data and the spreadsheet to produce the freqs for 300, 400 & 500 sized machines. It works spot on. I own a rather expensive mechanical belt tension gauge and the numbers match quite well doing the frequency method to the Gates specifications.

From Florent's doc.... peaks should be

300 86-100 hz

400 66-75 hz

500 53-62 hz

I personally am running right at 72 hz on my VC500 and get no belt slap on that belt section parallelizing the Y extrusions. I use to be able to watch the belts start vibrating during the resonance test. don't see it anymore.

MPE... YMMV

@ptegler I looked at their website and searched around for that write up and couldn't find it, if you have the link would you share that please?

Thanks, that was fast :D. I'll read up.

PS. Its not that I don't believe the method works or is unreliable, its phone microphones, apps and the procedure a person has to follow that I think is likely to produce unreliable results (hence i didnt really want to get into it 😉 ).