VC500 3.1 Long Standing Issues

Hello, my printer hasn't worked in nearly 6 months and I don't know how to fix it.

It is a VCore 500 3.1-ish. The following modifications have been made:

- Swapped to VC4 motor mounts.

- Using different joiners and a top mounted rail (but the problem persisted with the old joiners and Y-rail location)

- Using a frame mounted tensioner

- Using a toolhead of my own design with a Beacon probe. (But problem existed when using the rr toolhead with Beacon probe)

- No enclosure.

I've been working on this for so long, I don't even know what to try next. I think there's something fundamentally wrong with the printer. I've nearly given up hope that this will ever work

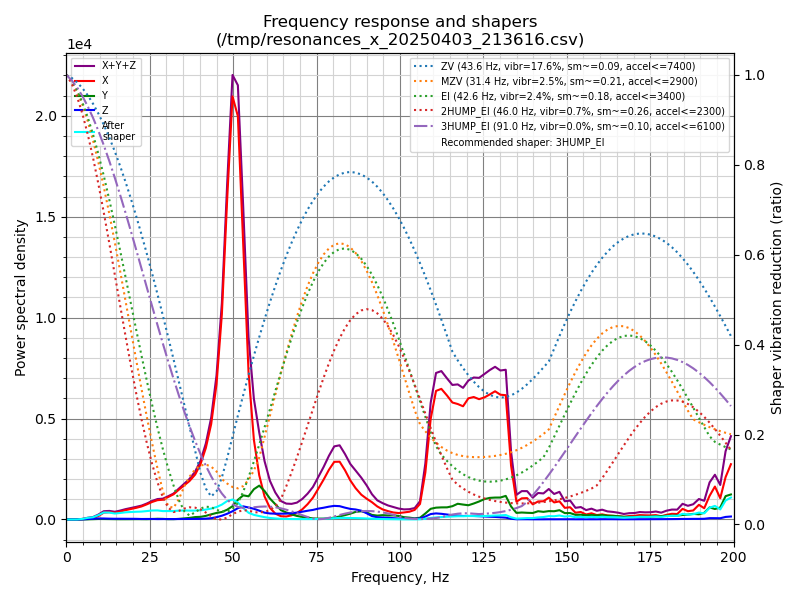

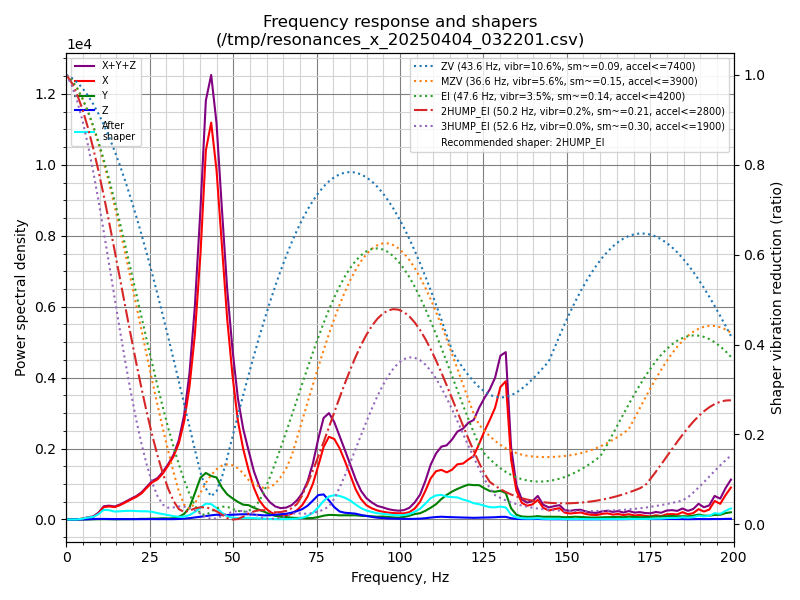

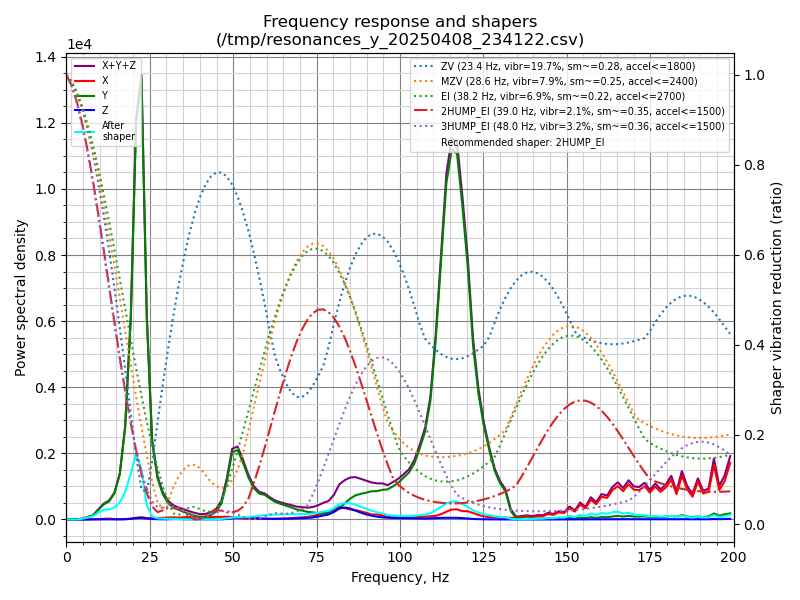

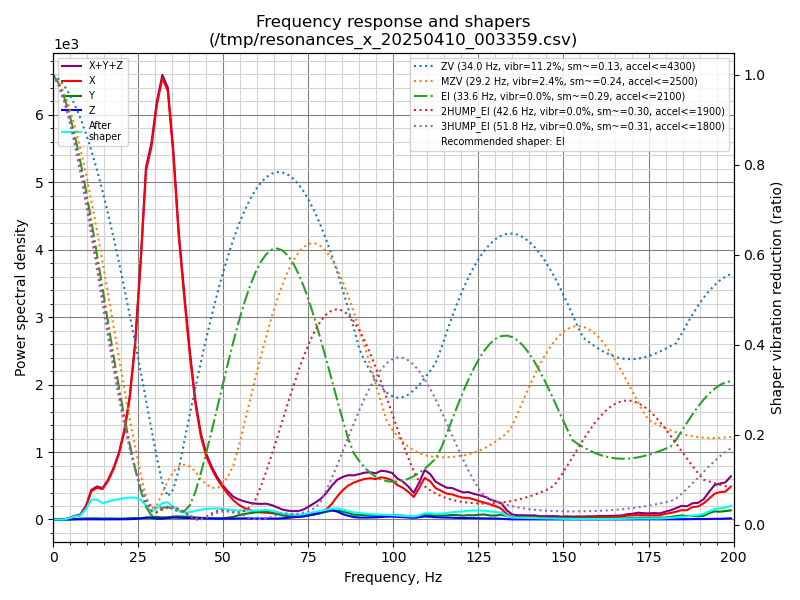

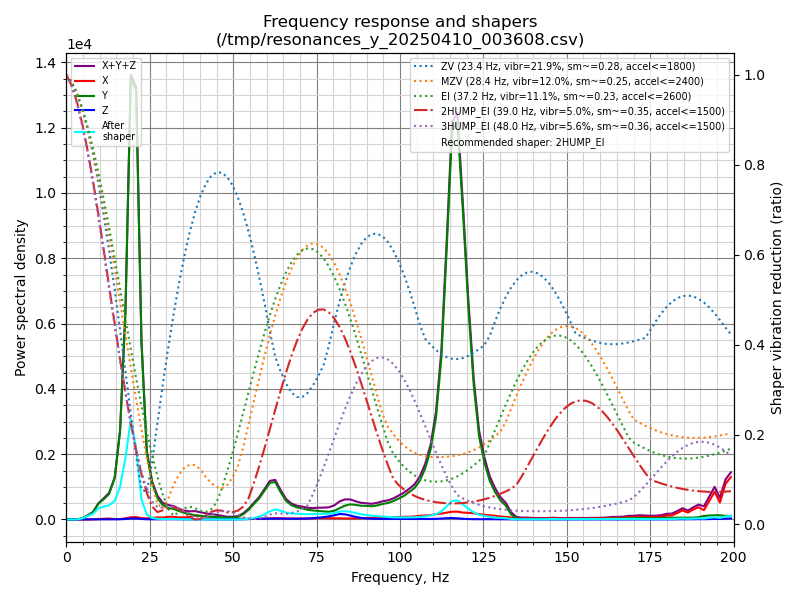

These are the most recent input shaper graphs, but I've got dozens.

42 Replies

gonna try posting shaper graphs as I test as something of a "log", or if anyone can figure out the idiocy i'm trapped in

I believe these are as loose as I can make them

Increasing the tension by an entire turn on each tensioner

the scale on the frequency comparison has shot up. I believe it was too loose before but is now too tight

X and Y are dramatically worse

loosened a half turn on each

still 1e6 on the comparison chart. I don't think relative tension is correct right now, but I don't think that's the issue either (yet)

Testing turning the motors off, rehoming, then re generating the graphs. I have not been doing so between tension changes. I do not think this will produce a change, but the thought occurs

No meaningful change

But it is slightly different

loosen quarter turn

i dont think i'm at a point where tensions matter that much. there is an underlying issue that I cannot find

Adjusting the screws on the side of the y rail carts. Both making them loose and then making them tight produced no meaningful change

i think i need to break the threadlocker I just put on the other day to test the joiner-cart screws.

but that takes 24 hours to cure when I reapply....

Tightening the screws binding the joiner plates to the rail carts as hard as i can with a single finger,

Loosened each plate-cart screw half a turn. None currently feel loose (ie, wiggles to the touch)

This is a different result, technically

Loosened each plate-cart screw an additional half turn. None currently feel loose (ie, wiggles to the touch)

This too is a different result. X shouldn't change much because I'm only touching the y rails now

Loosened each plate-cart screw an additional half turn. One currently feels loose (ie, wiggles to the touch)

Tightened the one loose plate-cart screw as tight as it can go with a finger

Completely removed the loose plate-cart screw. It may be that the threadlocker on that screw has been broken in this test and thus it will now either be loose and wobbly OR tight enough to interfere with the cart

is this... progress?

I think I need to disassemble my toolhead to loosen the screws on the x rail. but it's been 6 hours i would like to not be doing this

No, incorrect. I didn't notice that the plate screws were loosened enough that the entire y rail could be lifted a mm or two

Loosening all four screws on the x rail by half a turn

what a dreadful thing to have to test again

Loosening the screws on the x rail cart by an additional half turn

the entire toolhead can be wiggled on the cart now. I suspect the x cart screws are too loose. re tightening half a turn before investigating specific vibrations using the resonance analysis

the results of that re tightening

they're way worse than before, I suspect I missed something

I'm gonna try threadlocker and return in a few hours

Post threadlocker

I did notice a bit of belt folded inward, rubbing against the extrusion. I don't think that is leading to issue but I dont think that should be left untended

Tiny improvement after securing the belt ends

Loosen each belt by half a turn

trying adjusting the screws connecting the lgx pro to the baseplate

Swapped out the baseplate with a new one. It's only pla but it grabs the extruder by the sides and not the bottom

I have realized that posting every change in here makes it easier to compare graphs even if this is not useful to anyone. But it does mean I can show my due dilligence

replaced the previous toolhead baseplate with a new one that grips the motor by the sides. progress?

I tightened each belt by have a turn. Un-progress?

Loosened each belt by a half turn. this seems not better,

but tension may not be the issue

I had previously removed the cpap hose to see if that was a source of the issue (it was not). I shortened the hose and just now put it back into place

did more adjustment on the loom itself. I dont think that's the primary source of the problem but moving something around seemed to help the manual checks

what the fuck is that plateau on the x chart lol. how did i do that

how are you round

starting over tensioning from the top. as loose as I can make them

Turning each belt a full turn tighter

Additional full turn tighter

half turn tighter

Made a change in the tool head design where the duct met the baseplate. That may have been a source of vibration contact

I was incorrect