IDEX T1 not correctly bounded on X

After seemingly no changes to something that was working previously I have found that my T1 is considering x=500 to be substantially far off the side of the bed.

Debug steps so far:

- Deleted all of the

CALCULATE_DC_ENDSTOP details from my printer.cfg

- Performed _VAOC_RESET

- Restarted Klipper

- Calibrated VAOC

- Got CALCULATE_DC_ENDSTOP results and put them into printer.cfg

- Restarted Klipper

- Performed _VAOC_RESET

- Calibrated VAOC again

There has been no visible change to the position the toolhead considered x=500. My current printer.cfg is attached.Solution:Jump to solution

In any case, for the bot:

The solution was an issue with Rotation Distances for the X steppers. I am not sure why they were changed. They should be 40....

48 Replies

There's something weird about your Endstop calculation

For reference, this is mine:

I know there will be differences from setup to setup, but yours is wildly different

Compare mine to yours, and your DC endstop position and your X margin have been calculated to be more than 16mm further over

Your T1 parking position is also 16mm further over

If you go to your ratos_variables.cfg, what's your x_offset?

idex_xoffset = -0.024422091976362026

Strange that its so different

To be fair, I forget that I've made quite a few changes to my machine and it could have something to do with that. I'm using Mandala bed arms and Funssor XY joints etc, so all of that could potentially account for the difference. Better to make the comparison to someone that has the same setup as you

That seems reasonable.

I was printing previously with t1 with no problems. Retuned with GATS and this is happening. The difference just doesn’t make any sense. When I open VAOC the heads are in almost perfect positions immediately.

The difference is too large to be a problem with the endstop button. It’s approximately 15mm too far right

Interesting. Parking my T1 I can take T0 to x=487mm, but not further. Parking T0 I can take T1 all the way to x=0mm. The printer really thinks somewhere in the offsets that T1 is much further left than it is

Yeh something feels wrong in the configs. Did you change anything in the Configurator at any point like nozzle size and may have accidentally selected some wrong hardware?

No, haven't touched the configurator since before this problem existed

Everything is selected correctly

I don't suppose one of your backup configs would show what your offsets used to be?

Good thing to check, it's very different

Current

Old

Numbers are off by almost 15mm, so how far I roughly measured it to be off

Why TF is this persisting. Shouldn't the steps I took in the original post above have completely wiped it?

Yeh and those numbers are much closer to mine

I think something is wrong mechanically that is causing the endatop calculation to be off

What could be wrong that would cause that? Obviously the endstop switch, but it appears to be working just fine. It couldn't possibly account for 15mm of offset

And the offset is consistent on the other side of the bed, so it doesn't seem like it's skipping

How exactly did you do GATS?

Are your tensioners equal?

Gantry isn't racked?

Tensioners are equal, not certain what you mean about "racked" but the gantry is straight

Yep, just double checked and the gantry is straight

Everything moves cleanly with little friction

Racked is if the XY joints don't touch the front/back endstops at the same time. So deracking is ensuring that they do.

Which I presume is what you mean when you say the gantry is straight

Yeah, that's what I checked. They touch the front and back at the same time

Could there be a problem with T0 that is causing T1 to shift? Something like the idex offset being calculated for T1 as a difference from T0?

I still don’t know what would be wrong with T0 in that case

Did as hard of a reset as I figure I could without re-installing RatOS (Which I really don't want to do) and the DC position still just isn't right

What the hell is going on

Is there anyone that I should ask?

I'm hesitant to ping Helge, just because I feel certain it has to be a mechanical problem

I am absolutely sure it's not

This really feels like there is some sort of sticky state that I have failed to clear somehow

All of the reasonable mechanical failures are covered

- Gantry is not skewed

- All movement is smooth with absolutely no binding

- Belts are tightened evenly with reasonable force (GATS)

- Prints come out fine with both heads individually

Even if it is somehow a mechanical failure, help with understanding what the VAOC calibration does to calculate the DC Endstop might be useful. It seems that something has gone wrong there, be it mechanical or software

Short of re-installing RatOS (Which I would like to avoid) I've done everything that I can think of. Going to give a ping to @Helge Keck in hopes that you might have some idea as to what could be going on here.

dont have time atm, will have a look later today. in the meantime please share the debug.zip file and show a picture of T0 at X0

No big rush, will get those. Thanks in advance

Thats T0 at 0, 0, 0

you have an usual high tidex x offset of 16mm, this shoudl be below 1mm

Yeah I just noticed that something was off with that. I'm redoing it all. That wasn't the case earlier

please run vaoc reset, remove the additional config from the printer.cfg, then redo calibration. make sure the idex x offset is below 1mm

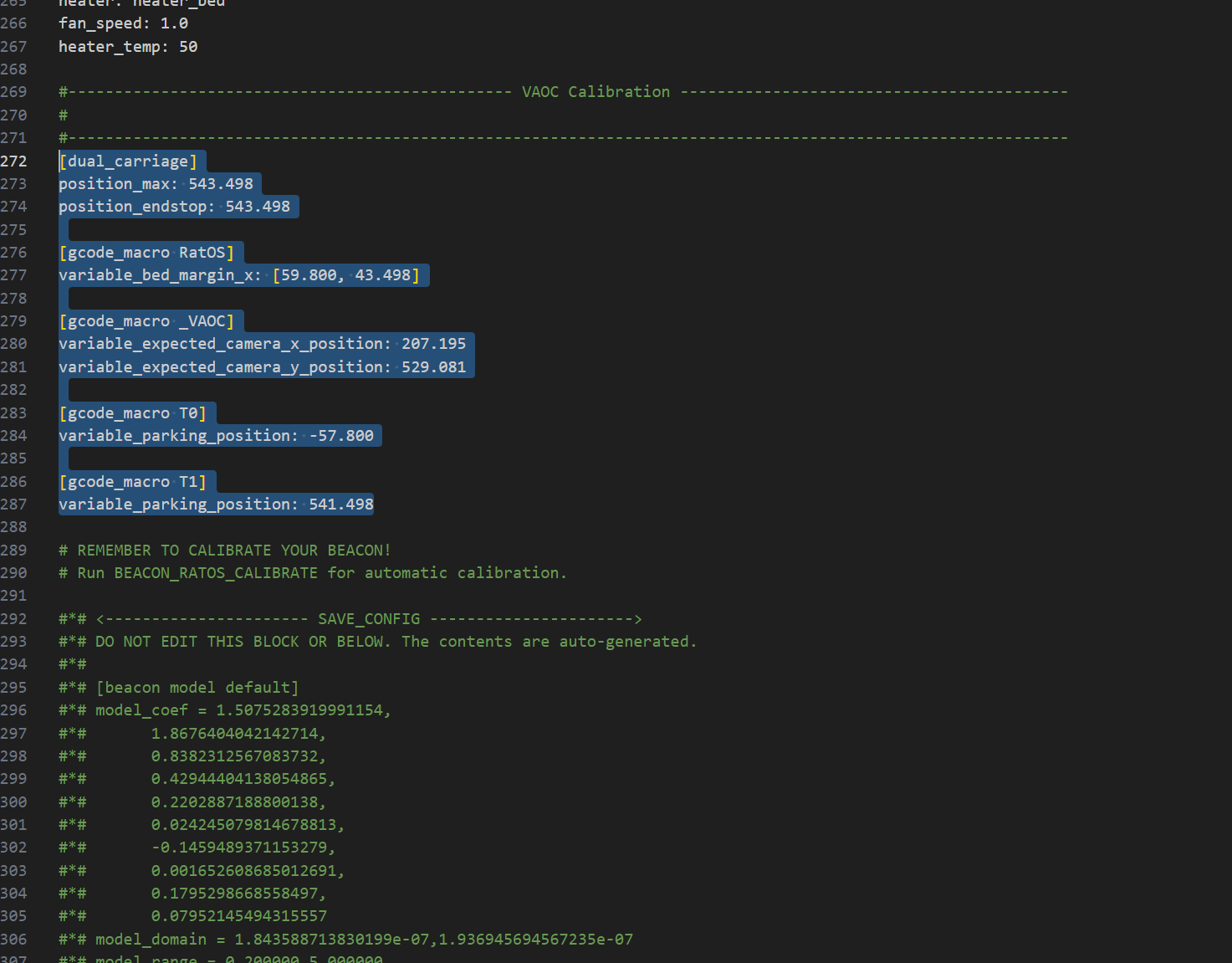

remove this from the printer.cfg before doing a new calibration

Yeah I must have left it half calibrated last time I was doing things. Not sure why. I'll do it all from scratch, the x offset used to be within the norm

I am losing my mind. 2 days ago there was no issues with this. Now it's fucked. What the hell is going on.

I haven't even touched the printer in those two days

Hard restarting the machine seems to have fixed the issue with the X offset. Extremely strange, it's like just deleting the section of printer.cfg, saving, and reloading klipper wasn't good enough

Okay, here we go, reasonable results.

T0 @ 0,0,0

T1 @ 500,0,0

show the toolhead panel from your web interface when t1 is at 500

move t1 to X0

and show the toolhead

The closest it will let me go to is 0.02. Will get that photo in a second

if you go to vaoc, are the nozzles aligned?

there is something wrong, these numbers do not make sense at all

you have a 15mm difference between t0 and t1 endstops positions

Yeah, they are

Yes, the issue does seem to be related to that

But I don't know why

do you ahve made any modifications to the etoolheads or endstops

Nope

completely stock

remove this from the printer.cfg

make a vaoc reset

restart printer

then test without a new vaoc calibraiton

test both toolheads at y0 and also at y500 and see if there is a difference to the edge of the bed

also, did you changed the rotation distance?

this value is not correct

should be 40

change it back to 40 please

totally possible that this is the issue

I never changed those. Very strange

Actually

Give me a second, maybe I did as part of something. One second

this are definitely not the stack values

Yeah I don't recall changing them. Strange. Will take them back to 40.

As for the test you mentioned with no VAOC calibration, T1 is about 2-3mm left of the position that T0 went to in both cases

It was consistent

Setting to 40 and redoing everything

Positions for the no VAOC are much more consistent now

I wish I knew why those values were changed

Yep. Everything comes out correctly now.

I am going to find where I was told to change those values. I know they aren't something I would have changed on my own.

Narrowed down the date from looking at backed up config files. From my messages here I was screwing with orbiter configs & proper z offset calibration. Both of those docs pages do no contain modifications to the rotation distance. None of the messages I sent referenced any changes to those values. I wonder why they got changed...

Solution

In any case, for the bot:

The solution was an issue with Rotation Distances for the X steppers. I am not sure why they were changed. They should be 40.

Thanks again for the help. Would have taken me ages to realize that on my own.