Y axis stutters during movement

So I am buildilng self-sourced vc4 500. During commisioning at bed mesh scan I noticed that Y axis moves slighy up and down. Also when I do slight movement from Mainsail just on Y direction, it starts with quite high vibration, that doesnt happened on X axis movement. I got mesh at 0.183 on a cold and very low gantry twist report. By hand all movements feel smooth.

What I did:

Checked pulleys;

Swapped stepper drivers;

Checked motors resistance - all windings equal;

X-Y joiners hit metal back plate equally at the same time;

Switched to standard mode from Performance, feels smoother but the issues still persist with moving Y up and down during bed mesh scan.

Please check video, it is hard to see the vibrations but it is there.

Any thoughts what it could be?

27 Replies

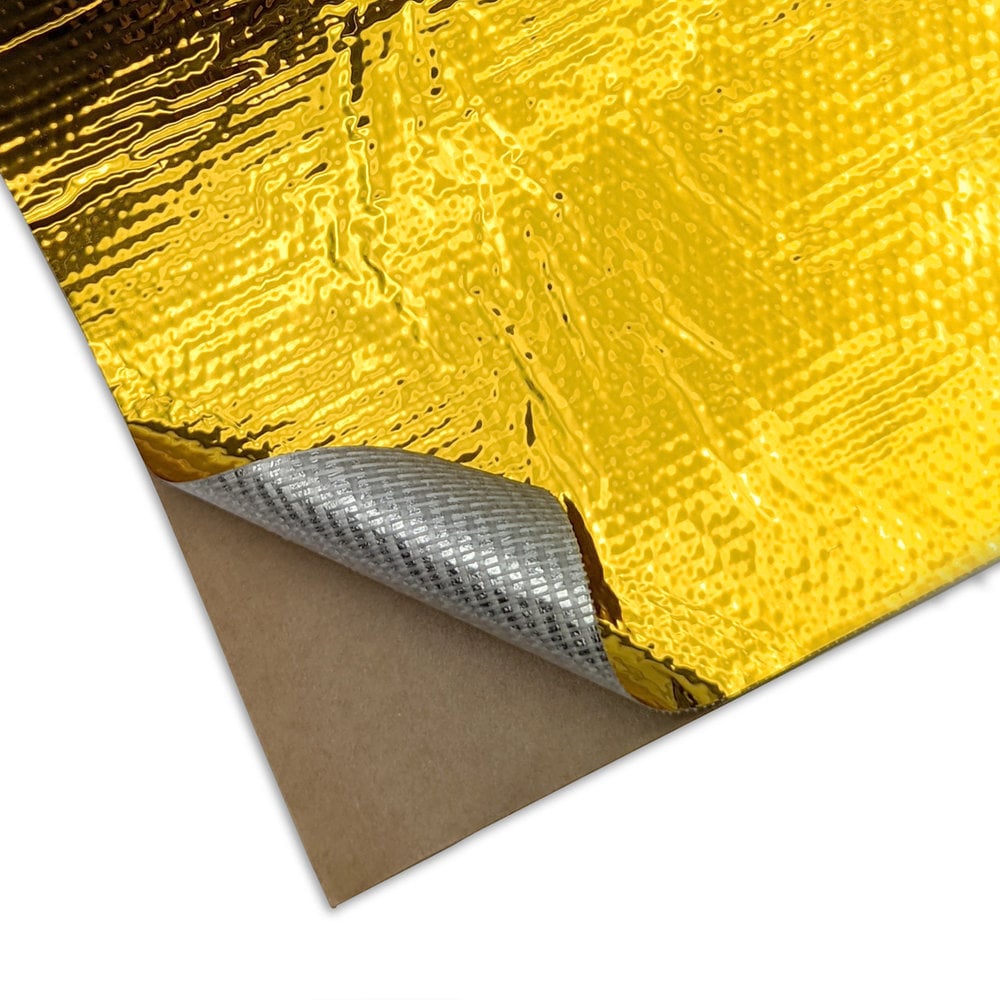

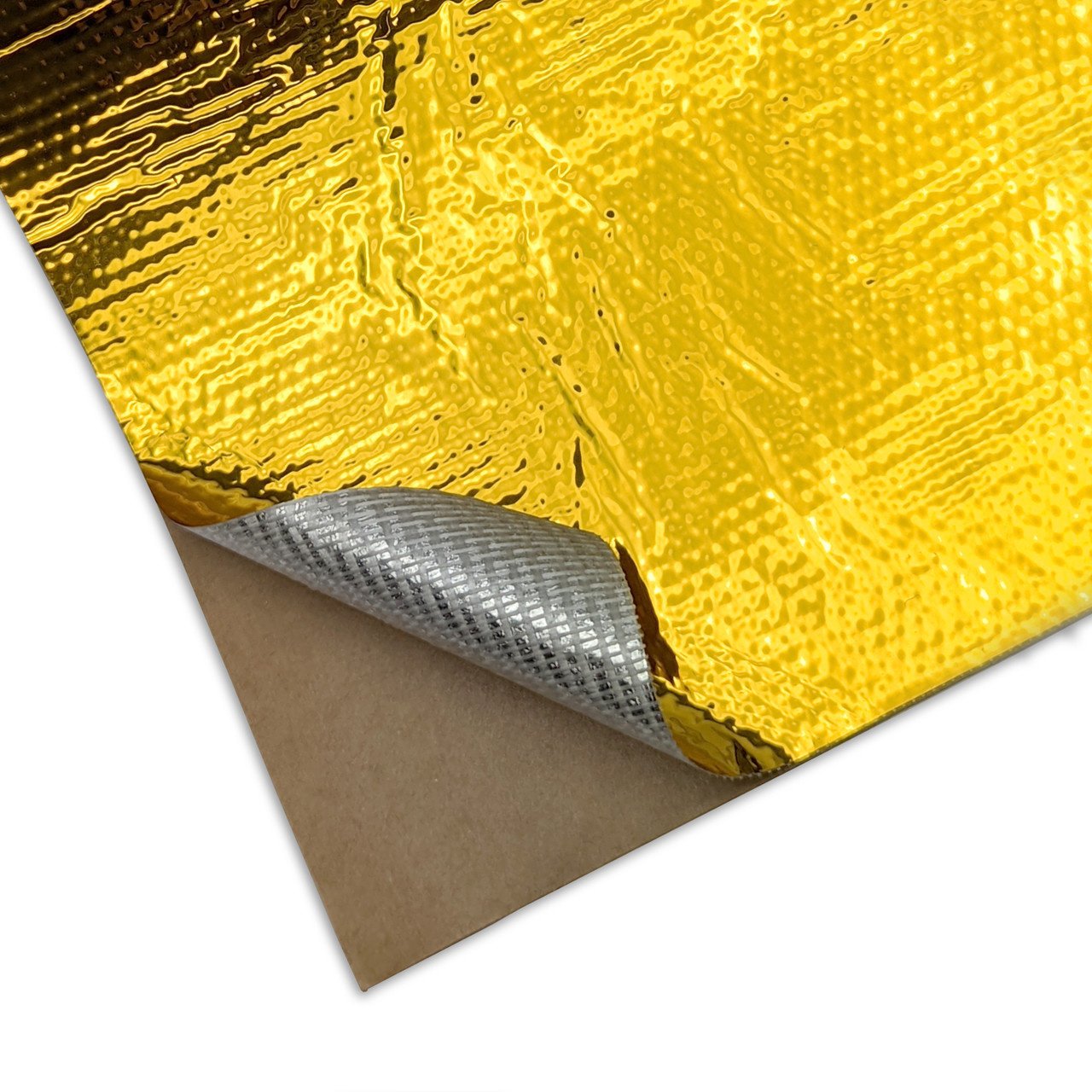

What foil do you have on your axis ?

Maybe bad motors

Are you on hybrid ? Or normal

Heat Shieldings B.V.

DEI Reflect-A-GOLD™ Hitte reflecterende gouden folie

Hitte reflecterende gouden folie van zeer hoge kwaliteit. Zelfklevend, makkelijk aan te brengen . Op voorraad en kan snel worden verzonden!!

I am on hybrid

I measured resistance on all stepers, between windings at 1.1 ohm equal, do you think that still can be faulty?

Yes maybe something on the Ball bearing or something

Maybe you can go back to normal just to check

I mean it is only to disconnect the belts from xy joiners a easy way to check

Thank you is it worth it ?

Ah sorry, I have hybrid config, but belts are not installed yet for hybrid.

Ah what if you go back to normal

And check again

I believe so and we print plenty of ABS/ASA 20-30 heatsl soak needed but no issues on first layer.

Do you mean to set config to not hybrid?

Yes

I would redo the configuration

And choose normal

Thats good one I will try it in 40 mins

👍 give me feedback

minutes*

Ah nice okay will give it a try

I have already a ti tube and heatsoak for 30 min but I think it still have problems on first layer

Only a few micro meters but yeah

Combo of ti tube plus foil might drop the heat soak time

Yes I will test it

Won't heat resistive tape increase the heat soak time? Or is the goal for the Ti Tube to not heat up?

ok something is really wrong, when I switched configuration to Standard from Hybrid, it start to home diogonally and also it doesnt move to the middle of the buildpldate. When it is homed I can still move it by hand diogonally, so one motor seams to not working? I did also set it back to Hybrid and it does work, at lest homes correctly. Image of Standard config attached also the video.

I think keeping it colder it helps.

Yes

Hmm and wich motor is the „defekt“ one

Or in wich direction can you still move it ?

Right motor is not working in Standard configuration, but in Hybrid it does work...

I am trying to switch stepper drivers now again

Yes maybe this next step I would change the motor with one of the hybrids

Yes, then I will be doing this, it is quite a work to dissasemble motor plates assemblies..

Yes I know … but yeah then we know if it is the motor or not

ok replacing stepper driver didnt helped

I will dissasemble motors plates, will update tomorrow!

@03Julian04 Ok I redid motors plates and gantry all over, the problem is still the same... during Y movements I can see the Y axis vibrates, also during scan it moves, please see the video

I dont believe it is squarness of skew of the printer somewhere, all readings I got is pretty good, flatnes of the bed is below 0.150, it got very low gantry twist report. All movements are very smooth by hand, no bidning what so ever.

My other vc500 doesnt move in Y during scan.

Also Y movements from dashboard not shaking up whole printer heavily.

Hmm at the moment my vc4 is disassembled because of some upgrades but if I got it back up I will test it on my machine

I know I recognised this on my machine too but ignored it and thought this is normal

But like I said after reassambleing it I will test it

Maybe your belts are not tight enough ? 🤔

Maybe when I install hybrid belts it will be gone 😄

I dont think so but I will play with it

Anyhow besides that, the machine vibrates a lot during movements it feels like it has very high start or jerk value during simple movements

My other vc4 doesnt vibrate when I move the gantry from the dashboard, it is also difficult to record on the camera.

It just has high jerk movement